About Transformers

The fault free operation of power transformers is a factor of major economic importance and safety in power supply utilities and industrial consumers of electricity. In the current economic climate, Industries/Supply Utilites tighten their control on capital spending and make cutbacks in maintenance, an increased awareness is placed on the reliability of the existing electric power supply. Down time is at a premium. Often, the loading is increase on present units , as this will defer purchasing additional plant capacity. Thus the stress on the transformer increases. The net total effect of the thermal , electrical and mechanical stress brought on by increased service needs to be monitored to ensure reliability.

Regular sampling and testing of insulation oil taken from transformers is a valuable technique in a preventative maintenance program. If a proactive approach is adopted based on the condition of the transformer oil, the life of the transformer can be extended.

This paper reviews some of the transformer oil tests and there significance.

Test Method IEC 814

Water, in minute quantities, is harmful in power equipment because it is attracted to the places of greatest electrical stress and this is where it is the most dangerous. Water accelerates the deterioration of both the insulating oil and the paper insulation, liberating more water in the process (heat catalysed). This is a never ending circle and once the paper insulation has been degraded(loss of mechanical strength) it can never (unlike the oil) be returned to its original condition.

Origins of Water

Water can originate from two sources.

Atmospheric

Via the silica gel breather (dry silica gel is always blue). Via leaks into the power equipment, i.e. bad gasketing, cracked insulation, a loose manhole cover, a ruptured explosion diaphragm etc. (if oil can get out, water can get in).

Internal Sources

Paper degradation produces water. Oil degradation produces water. Wet insulation contaminates the oil, (temperature dependent).

Test Method: IEC 156

The dielectric strength of an insulating oil is a measure of the oils ability to withstand electrical stress without failure. The test involves applying a ac voltage at a controlled rate to two electrodes immersed in the insulating fluid. The gap is a specified distance. When the current arcs across this gap the voltage recorded at that instant is the dielectric strength breakdown strength of the insulating liquid.

Contaminants such as water, sediment and conducting particles reduce the dielectric strength of an insulating oil. Combination of these tend to reduce the dielectric strength to a greater degree.

Clean dry oil has an inherently high dielectric strength but this does not necessarily indicates the absence of all contaminates, it may merely indicate that the amount of contaminants present between the electrodes is not large enough to affect the average breakdown voltage of the liquid.

Test Method: ASTM D974

Acids in the oil originate from oil decomposition/oxidation products. Acids can also come from external sources such as atmospheric contamination.

These organic acids are detrimental to the insulation system and can induce corrosion inside the transformer when water is present. An increase in the acidity is an indication of the rate of deterioration of the oil with SLUDGE as the inevitable by-product of an acid situation which is neglected.

The acidity of oil in a transformer should never be allowed to exceed 0.25mg KOH/g oil. This is the CRITICAL ACID NUMBER and deterioration increases rapidly once this level is exceed.

Polychlorinated biphenyl’s (PCB) is a synthetic transformer insulating fluid, that has found its way into mineral insulating oil via cross contamination.

POLYCHLORINATED BIPHENYL: Non-specific methods that determines Chlorine in oil, as all PCBs contain some amount of Chlorine. This test is susceptible to false positive results, i.e. the test indicates the presence of PCB when actually there is none present.

POLYCHLORINATED BIPHENYL: Specific method (ASTM D4059-Gas chromatography/Electron Capture) that differentiates between PCBs and a related compound e.g. trichlorobenzene. All commercially produced PCB are complex mixtures of many different congeners (A congener is a PCB molecule containing a specific number of chlorine molecules at specific sites) Analysing for PCB, therefore, is not a case of simply finding an easily quantifiable compound, but of quantifying a complex mixture of compounds.

The main reasons for stopping further use are the environmental risks. PCB is very stable and its degradation process is slow, it is also Biological accumulative in the food chain.

Far more serious are the risks of a fire or an explosion. At temperatures around 500 degrees C extremely toxic compounds Polychlorinated dibenzfuranes are formed. Small amounts of these compounds have been found at accidents where transformers and capacitors have been exposed to fire or have exploded. Even if the amounts have been extremely small and have caused no personal injuries, it has been necessary to perform very extensive and costly decontamination work.

Direct Evaluation

The mechanical properties of insulating paper can be established by direct measurement of its tensile strength or degree of polymerization (DP). These properties are used to evaluate the end of reliable life of paper insulation. It is generally suggested that DP values of 150-250 represent the lower limits for end-of-life criteria for paper insulation; for values below 150, the paper is without mechanical strength. Analysis of paper insulation for its DP value requires removal of a few strips of paper from suspect sites. This procedure can conveniently be carried out during transformer repairs. The results of these tests will be a deciding factor in rebuilding or scrapping a transformer.

Furaldehyde Analysis

Direct measurement of these properties is not practical for in-service transformers. However, it has been shown that the amount of 2- furaldehyde in oil (usually the most prominent component of paper decomposition) is directly related to the DP of the paper inside the transformer.

Paper in a transformer does not age uniformly and variations are expected with temperature, moisture distribution, oxygen levels and other operating conditions. The levels of 2-furaldehyde in oil relate to the average deterioration of the insulating paper. Consequently, the extent of paper deterioration resulting from a “hot spot” will be greater than indicated by levels of 2-furaldehyde in the oil.

For typical power transformer, with an oil to paper ratio of 20:1, the 2-furaldehyde levels have the following significance:

Other Diagnostic Compounds

The presence of phenols and cresols in concentrations greater than 1 ppm indicate that solid components containing phenolic resin (laminates, spacers, etc.) are involved in overheating.

The “predicted” DP (degree of polymerisation) indicates an average paper condition over the whole transformer (subject to factors such as effective circulation). New Kraft paper has a DP in excess of 1200, and paper with a DP of 200 or less is considered to be unfit (subject to interpretation).

The values can be optimistic if the oil has been regenerated within the last two years. This data should be evaluated in conjunction with routine chemical analysis and transformer history.

Test Method IEC 567

Transformers are vital components in both the transmission and distribution of electrical power. The early detection of incipient faults in transformers is extremely cost effective by reducing unplanned outages. The most sensitive and reliable technique used for evaluating the health of oil filled electrical equipment is dissolved gas analysis (DGA).

Insulating oils under abnormal electrical or thermal stresses break down to liberate small quantities of gases.The qualitative composition of the breakdown gases is dependent upon the type of fault. By means of dissolved gas analysis (DGA), it is possible to distinguish faults such as partial discharge (corona), overheating (pyrolysis) and arcing in a great variety of oil-filled equipment.

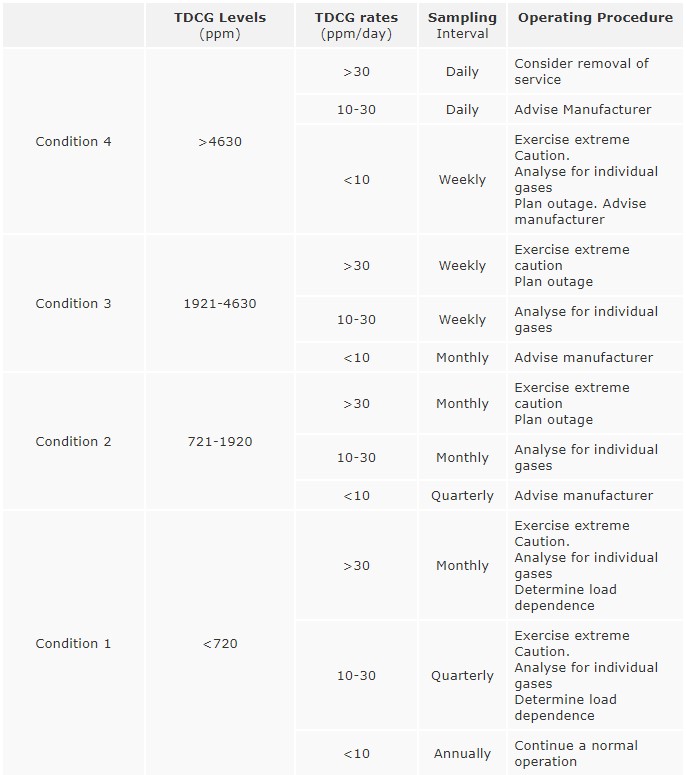

Information from the analysis of gasses dissolved in insulating oils is valuable in a preventative maintenance program. A number of samples must be taken over a period of time for developing trends. Data from DGA can provide

- Advance warning of developing faults.

- A means for conveniently scheduling repairs.

- Monitor the rate of fault development

NOTE : A sudden large release of gas will not dissolve in the oil and this will cause the Buchholtz relay to activate.

By separating and quantifying (measuring) the gasses found dissolved in the oil, the specialist can identify the presence of an incipient fault (early warning).

The amounts and types of gases found in the oil are indicative of the severity and type of fault occurring in the transformer.

The separation, identification and quantification of these gases requires the use of sophisticated laboratory equipment and technical skills and therefore can only be conducted by a suitably equipped and competent laboratory.

Other higher hydrocarbon gases are produced, but these are not generally considered when interpreting the gas analysis data.

Conclusion

Analysing insulating oil taken from transformers is a unique way of identifying problems occurring within a transformer.

By identifying and quantifying the gases found in transformer oil, the condition of the transformer can be monitored.

If faults are found to be occurring, outages can be planned and the fault can be rectified before major damage can occur.

The interpretation of transformer oil gas analysis is still an art and not an exact science. The interpretation should be left to a specialist and his advice and recommendations should be followed. Samples should be taken regularly and records kept.